Sustainable composite materials

We believe that chemistry can help the composites sector move towards more sustainable practices.

Composites are strong, lightweight materials that are critical in driving the transition to a carbon-neutral world. But their production, manufacture and end-of-life carry their own environmental cost.

We believe that chemistry can help the composites sector move towards more sustainable practices. Our technical report explores the role of chemistry as both a barrier and an aid to overcoming sustainability challenges.

In collaboration with Sustainable Composites, a partnership between the National Composites Centre (NCC) and Centre for Process Innovation (CPI), we consulted academia and industry to investigate a particular group of composites: fibre-reinforced polymers, or FRPs. FRPs are used in a wide range of industries because of their lightweight properties, strength and durability. Their continued use and growth into new markets is important to the UK economy and the UK’s legal commitment to achieving net zero emissions by 2050.

On this page

110,000

The number of tonnes of fibre-reinforced composites produced in the UK each year – more than twice the weight of the Forth Rail Bridge.

6%

The proportion of fibre-reinforced polymer composite materials reused in secondary applications

>95%

The percentage of fibre-reinforced polymers made from virgin materials derived from fossil fuels.

£4bn

The annual value of the UK composites market in 2019 which is set to soar.

Our report

This report is an important first step in ensuring that chemistry plays its full part in the composites supply chain, helping the sector move towards more sustainable practices.

This report is for:

- Industry including raw material producers, resin formulators and manufacturers who are producing glass and carbon fibre reinforced composites.

- Composites users in aerospace, automotive, construction and infrastructure, defence, hydrogen, marine, oil and gas, rail and wind sectors.

- Recycling companies and waste businesses that deal with composite parts at end of life, including manufacturing waste.

- Academics working in the fields of polymer chemistry, analytical chemistry, green chemistry, sustainability, chemical recycling, bio-derived feedstocks, and industrial products and processes.

- Trade associations and technical and interest groups who bring together members of the chemistry, composites and materials communities.

- Policy influencers working on an advanced materials strategy and public funding for the chemistry and composites sector.

Read our report

This report captures the findings from an investigation conducted by the Royal Society of Chemistry and Sustainable Composites, in consultation with academia and industry. It provides an overview of the opportunities to bring chemistry-based solutions into the UK composites supply chain for the purposes of delivering sustainability within the sector.

Our action plan

The Royal Society of Chemistry, the National Composites Centre and CPI are committed to advancing the development of sustainable solutions for the composites industry.

Our action plan sets out the ways in which we will help to influence change.

The Royal Society of Chemistry will:

- Champion new research. We will create opportunities for chemical scientists to publish peer reviewed studies on sustainable composites and encourage members of the composites community to ‘step into’ the chemistry research domain.

- Promote skills development. We will upskill chemical scientists through learning opportunities, careers guidance and chartership to increase participation in the composites field.

National Composites Centre and CPI will:

- Encourage collaborations. We will convene experts to de-risk and support industry to develop sustainable solutions.

Composites at a glance

Composites are made from two or more constituent materials, each with different properties. When combined, they create a material with properties greater than the sum of its parts. Examples include polymer, ceramic, and metal matrix composites.

Fibre-reinforced polymers (FRPs) are a subset of polymer matrix composites and the focus of our Chemistry-enabled sustainable composites report.

Both strong and lightweight, FRPs are used in a wide range of industries where high-strength structures are required.

The main types of composite materials Picture: National Composites Centre / Royal Society of Chemistry

FRPs are composite materials made from a thermoset or thermoplastic polymer that is reinforced with fibre, typically carbon or glass. The main advantages of FRPs are their durability, design freedom, low weight, high strength and stiffness. Visit the NCC website to explore the roles of composites in everyday life.

Applications in industry include:

- wind turbine blades

- gas (e.g. hydrogen) and liquid tanks and pipes

- aeroplane wings, fuselage, empennage and interiors

- vehicle body panels and interiors

- roofs, pipes, cladding, window frames

- foot, road and rail bridges

- military equipment

- the hull, deck and masts of boats.

Fibre-reinforced polymer composites (FRPs) consist of strong fibres embedded in a resin matrix.

When a composite is put under load each individual fibre bears a degree of that load. The resin acts to hold the fibres in position and protects them from damage and degradation (cracking, for example). The alignment of the fibre direction and overall design of the structure is, therefore, typically arranged around the desired load requirements and associated design envelope. The selection of the matrix is usually based on the environmental conditions (for example, exposure to heat, light, moisture) the application will operate within.

| Thermoset | Thermoplastic | |

|---|---|---|

| Chemistry | Crosslinking between polymer chains forms a very stable crosslinked matrix | Weaker associations between the polymer chains rather than cross-linking bonds to form a reformable system |

| Examples | Wind turbine blades, aeroplane wings, hydrogen storage tanks | Automotive interior trim, oil and gas pipes |

| UK market share (value) in 2019 | Epoxy = 43% | Polypropylene= 9% |

| Unsaturated polyester = 38% | Polyamide = 6% | |

| Vinyl ester = 3% | Other = 1% | |

| Total = 84% | Total = 16% |

The main fibres used in composites are glass and carbon. Carbon fibre, however, has an environmental impact approximately 10 times larger than that of glass fibre because of how it is made.

In addition to resins and fibres, composites contain a variety of other components, which add additional functionality such as toughening agents and coatings.

| Glass fibre | Carbon fibre | |

|---|---|---|

| Feedstock | Primarily derived from silica (sand) | Can be derived from many sources but the dominant source is petrochemical derived acrylonitrile |

| Production | Glass is drawn into fibres | Polyacrylonitrile (PAN) is drawn into fibres. Multiple processing steps remove acrylonitrile functionality and generate the highly unsaturated graphitic poly-crystalline structures which are the bulk of the ultimate fibre product |

| Examples | Wind turbine blades, boat hulls, bridges | Wing structures, hydrogen tanks, Formula 1 car parts |

| UK market share (value) in 2019 | 59% | 41% |

The major advantage of composites compared to other engineering materials, such as metals, is their strength- (and stiffness) to-weight ratio. The combination of polymer and, typically, carbon fibre used in composites have an overall lower density than engineering metals like steel and aluminium. They can, therefore, achieve the same or better mechanical performance for less weight.

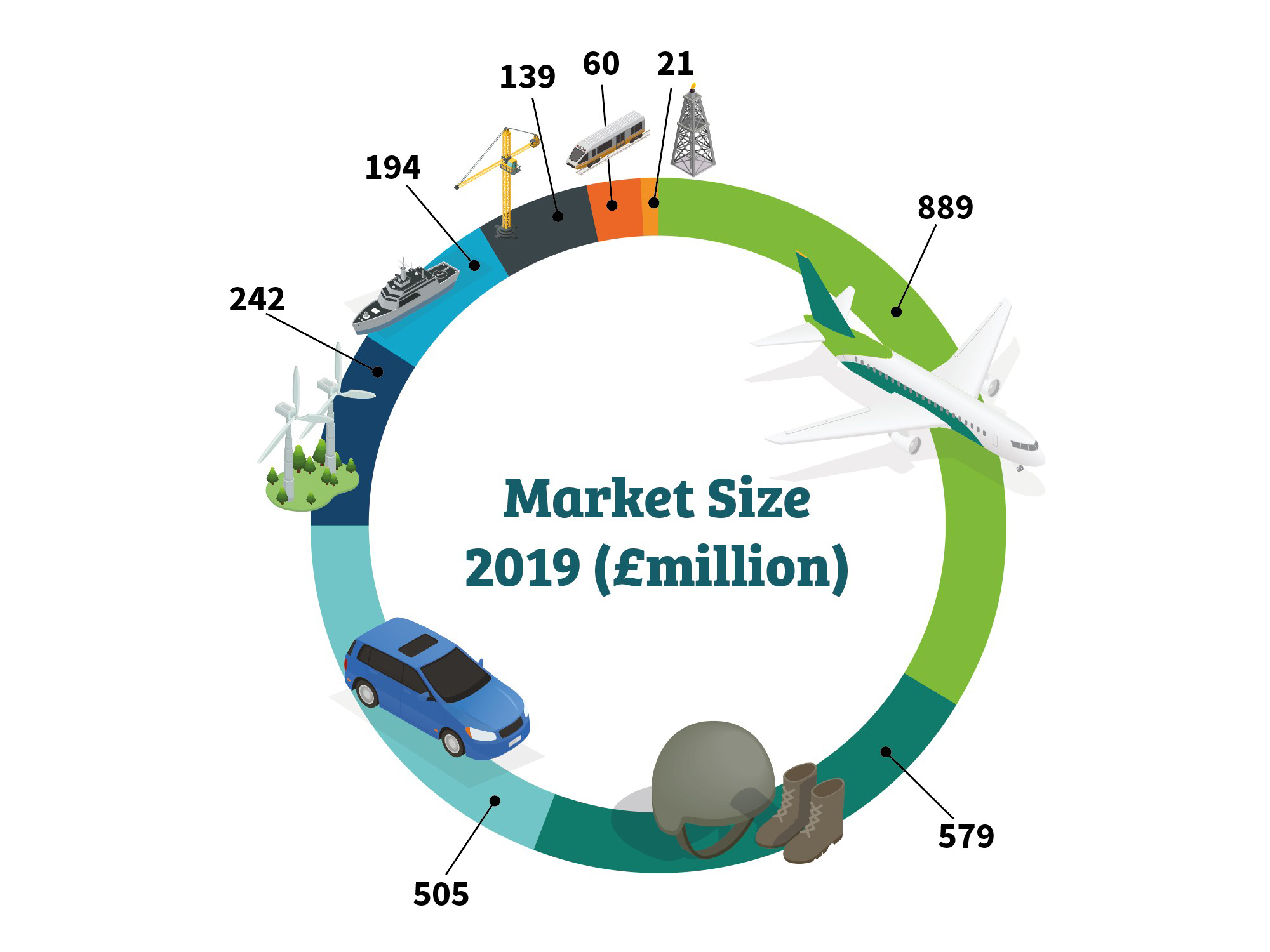

The UK is a world leader in composite manufacture. In 2019, the UK composites market was worth £4 billion and is expected to reach £6.3 billion in 2035.

FRPs are widely used in aerospace, automotive, construction and infrastructure, defence, marine, oil and gas, rail, and wind. The growing hydrogen market is also expected to place significant demand on supplies of carbon fibre polymer composite.

How FRPs contribute to net zero:

- As well as their contribution to the UK economy, FRPs are crucial to delivering the UK’s net zero targets by 2050.

- FRPs are used in renewable energy technologies, such as wind turbine blades.

- They enable the lightweighting of transport to reduce carbon dioxide emissions.

- Their durability extends the lifetime of infrastructure.

- They are likely to be in demand for hydrogen storage and transportation.

Pie chart showing a breakdown of selected segments of the UK composites industry as at 2019. Picture: Lucintel / Royal Society of Chemistry

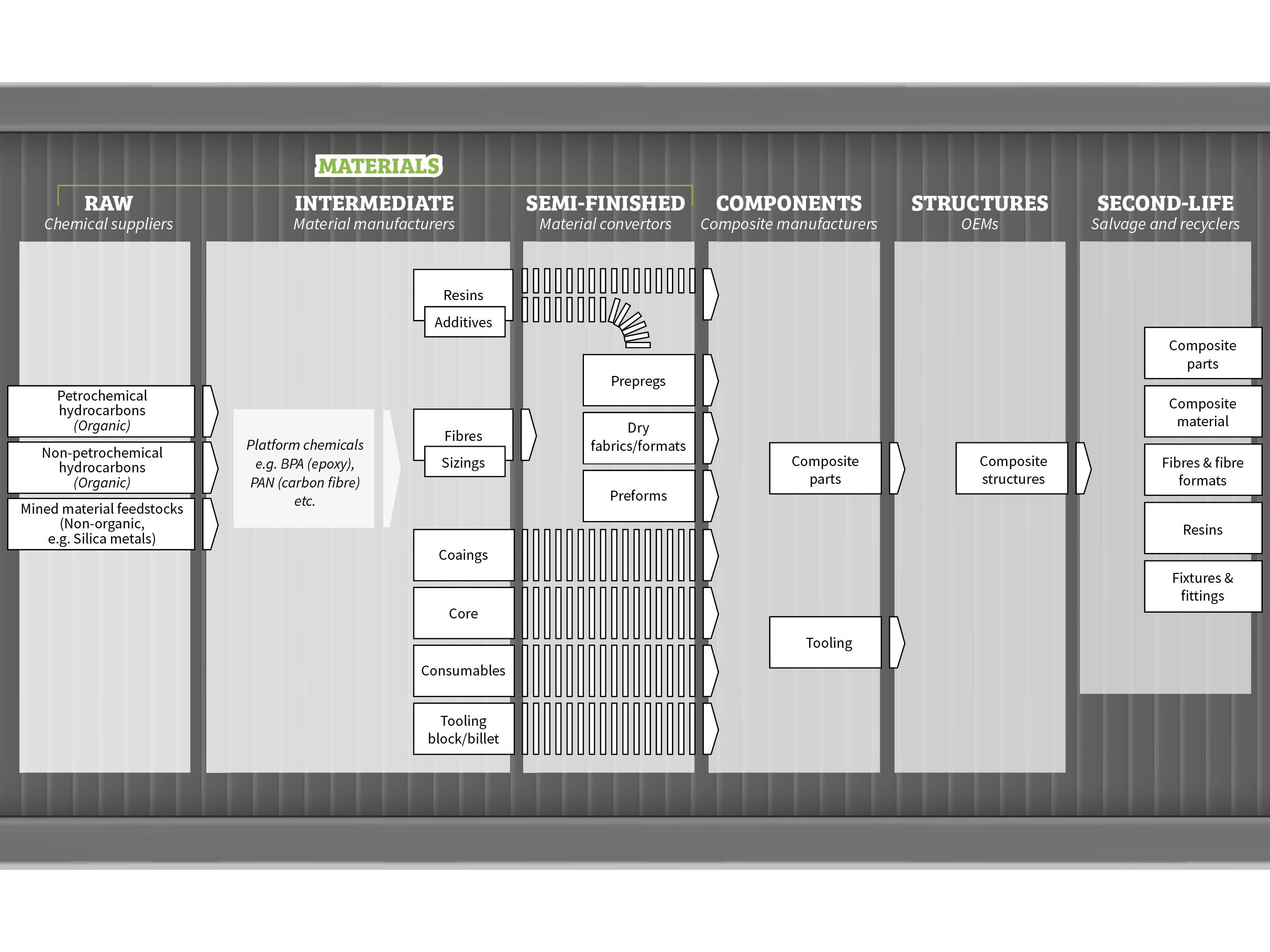

The sourcing of materials and formulations required to manufacture composites is a global operation.

Chemical producers tend to supply raw materials to other formulators rather than directly to composites manufacturers.

In the UK, many of the raw materials used in the composite industry, such as glass and carbon fibres, are imported. For example, the UK’s wind energy market imports over 60% of composite parts.

The diagram below summarises the composite supply chain and the different types of companies involved.

Schematic representation of the composite supply chain Picture: National Composites Centre / Royal Society of Chemistry

Nearly all (95%) FRPs are made from virgin materials derived from fossil fuels. While their durability means that they can be in use for many years, most FRPs end up in landfill at the end of their life.

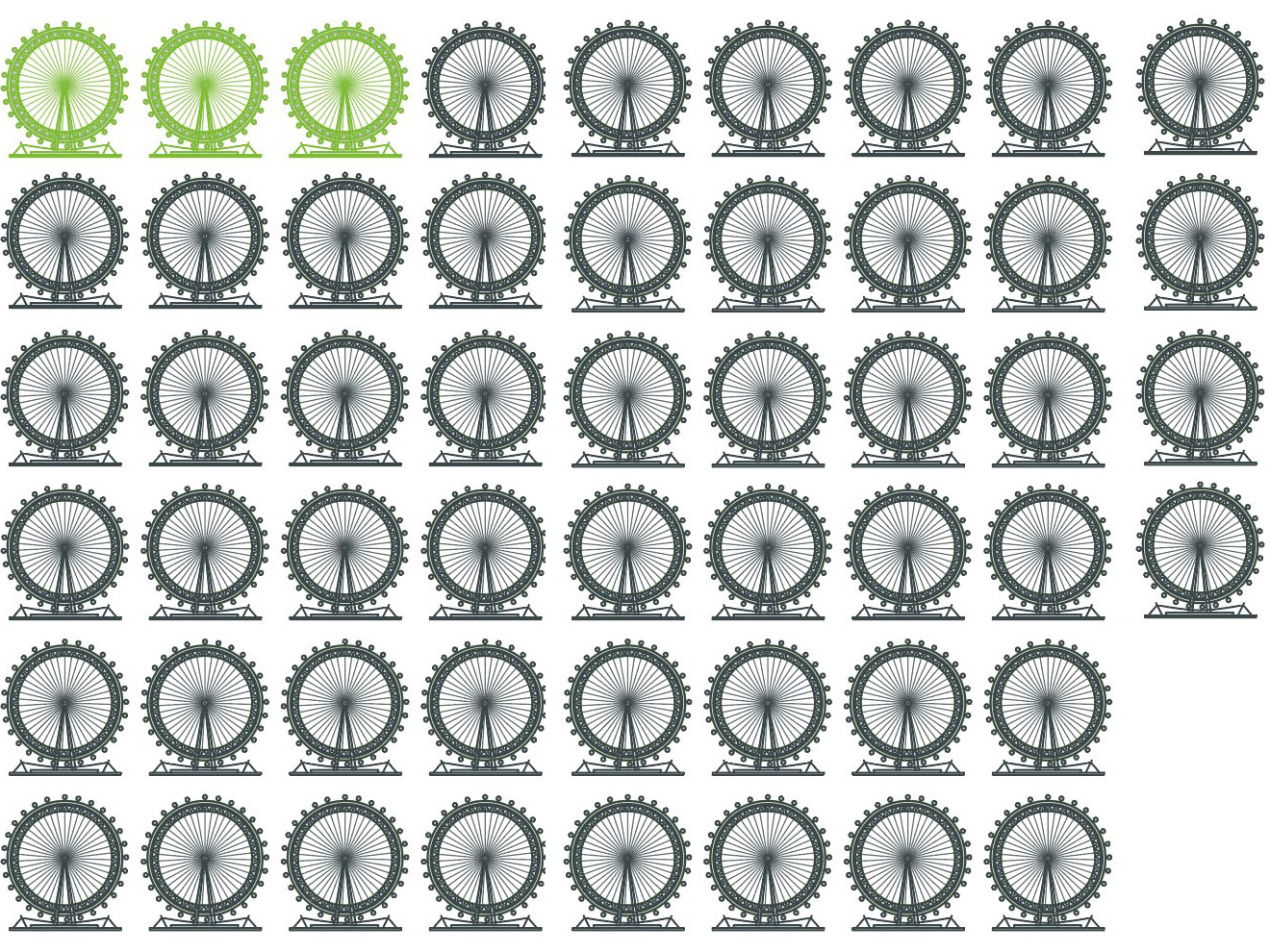

In 2019, around 110,000 tonnes of FRPs were produced in the UK.

Those 110,000 tonnes of FRPs weigh as much as 52 London Eyes.

However, just 6% of composite material will be reused in secondary application. 94% will be landfilled or incinerated.

We need to move away from the current petrochemical-based linear supply chain to a more sustainable model based on a circular economy. This will mean that sustainably sourced materials are fed into a closed loop with minimal subsequent losses during manufacture and at end of life.

The current composites industry follows a linear economy:

- Raw materials derived from non-renewable resources

- Manufacture

- Use

- Landfill or incineration

For a more detailed analysis of sustainability trends, go to section seven of our sustainable composites technical report.

Sustainability and the composites sector

Composite materials need the high performance, durability and environmental resistance of FRPs in order to contribute to delivering net zero. However, they are exceptionally challenging to manage at end of life. A fundamental change is therefore required in the sustainability of these materials and the supply chain.

In our Chemistry-enabled sustainable composites technical report, we explore the challenges and opportunities of sustainable composites using three principles.

The composites supply chain needs to move away from a linear economy that relies on non-sustainable feedstock and the landfilling of material. Instead, a circular economy needs to be developed where sustainably sourced materials are fed into a closed loop with minimal subsequent losses during manufacture and at end of life.

The future circular economy model for wind turbines, created within the SusWind programme and based on the Ellen MacArthur Foundation's three principles

The future circular economy model for wind turbines, created within the SusWIND programme and based on the Ellen MacArthur Foundation's three principles Picture: SusWIND / Royal Society of Chemistry

Find out more about SusWIND here.

The EU waste hierarchy ranks waste management options according to what is best for the environment. The UK uses this framework to set out guidance for any business or public body that generates, handles and treats waste.

Until now composites have been designed for maximum performance with little consideration of the impact of their production or waste.

Waste hierarchy infographic

The EU waste hierarchy Picture: European Commission / Royal Society of Chemistry

Decarbonising industry is part of the UK Government’s legal commitment to achieve net zero greenhouse gas (GHG) emissions by 2050. For the composites supply chain, this means reducing the impact of the sourcing, production, use and disposal of composites. This needs to happen without limiting the ability of composites to deliver current needs, especially where they can be enablers for green technologies.

Read more about the key sustainability principles in section 6.2 of our Chemistry-enabled sustainable composites technical report.

Six sustainability trends

Our report highlights six sustainability trends that industry and academic experts identified. They cover the production, use, and end of life of FRPs.

The composites supply chain needs to move away from a linear economy that relies on non-sustainable feedstock and the landfilling of material. Instead, a circular economy needs to be developed where sustainably sourced materials are fed into a closed loop with minimal subsequent losses during manufacture and at end of life.

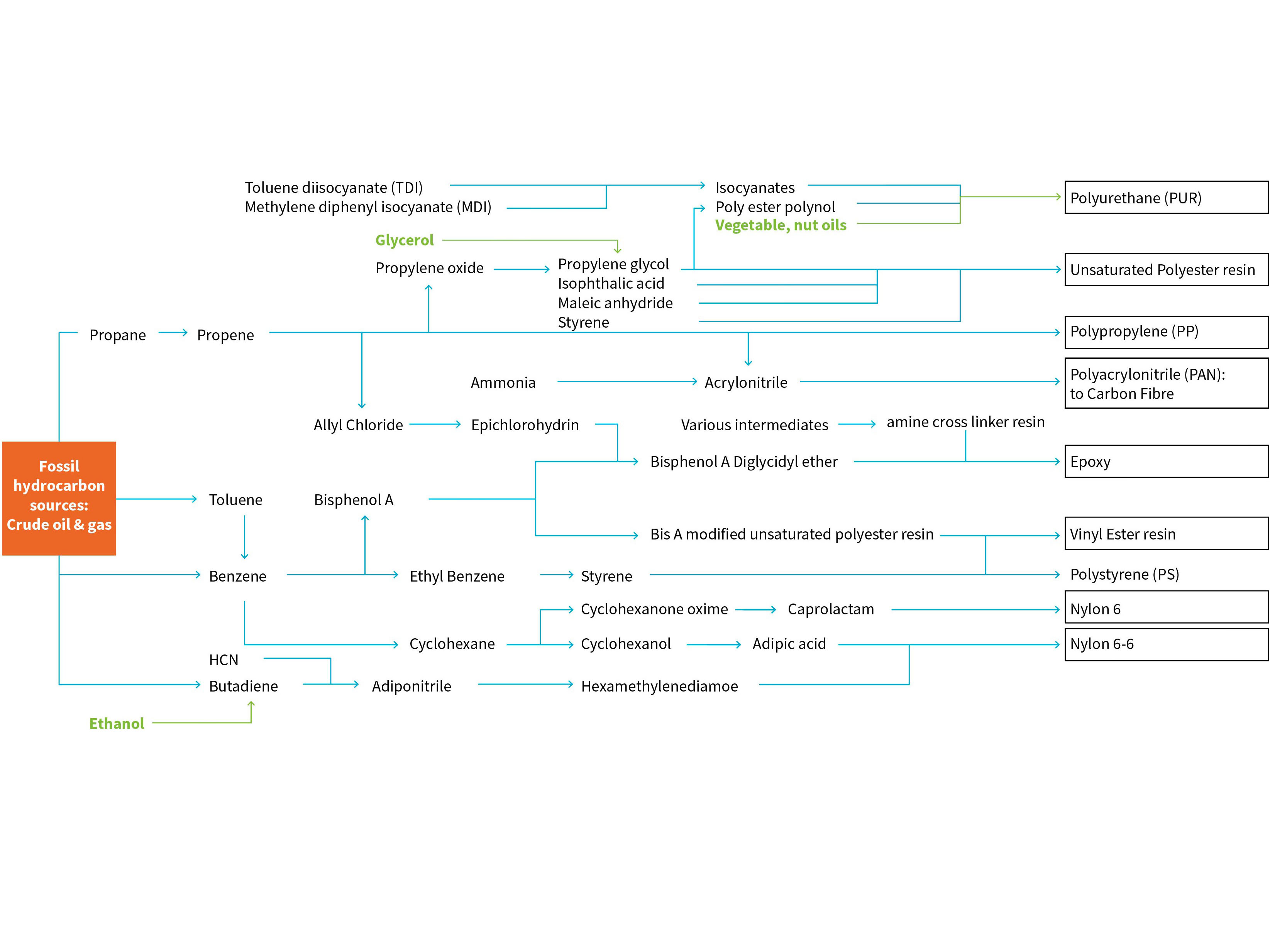

A summary of the major organic chemical types involved in the supply chain of precursors and composites production. Picture: Centre for Process Innovation Commission

Nearly all polymer and fibre feedstocks used in the composites industry are derived from non-renewable sources. This introduces new carbon into the environment. Some companies are exploring alternative sources of carbon, including:

- bio-feedstocks such as ethanol derived from sugar cane, and certain grasses and bio-waste from agriculture and forestry

- waste materials, such as polymers and plastics (circular economy)

- the conversion of CO2 itself to useful materials and products.

The chemical industry is also evolving to decarbonise the processes used to convert base materials to formulated products. This is being done by reducing the energy demand of chemical processes and by improving their efficiency.

Low carbon thermoplastics

Thermoplastics are one of the two main types of polymers used in composites, with polypropylene and polyamides particularly prominent. As companies reassess the way these plastics are produced, new technologies are emerging that could reduce carbon emissions during manufacture, albeit at a sizeable short-term cost.

Low carbon thermosets

The supply chain for thermosets is more complex than thermoplastics as they are multicomponent systems. They are created by combining mixtures of various agents, catalysts, oligomers and monomers. The two most common types are epoxy resins and unsaturated polyesters.

Progress is being made towards reducing the environmental footprint of thermosets. Examples of this include:

- Efforts to reduce the amount of carbon used to produce unsaturated polyester resins are underway.

- Low carbon routes to styrene monomer are being investigated so that bio-waste-derived feedstocks could be used.

- New bio-routes to glycols and anhydrides have been identified by a number of companies around the world. Some are in use commercially.

A bio-based epichlorohydrin derived from vegetable glycerol offers hope that epoxy resins could be produced with a significantly reduced carbon footprint. There are also developments in the supply chain that could help curb the carbon demands of the bisphenol A.

Bio-derived resins

Bio-derived resins can offer new chemical approaches to deliver composite performance at acceptable cost. Most bio-derived resins are derived from biomass feedstocks. These include plant oils, lignocellulosics and plant-based polysaccharides, and sugars from waste biomass.

Three promising resins and materials for industry are:

- polyfufuryl alcohol (PFA), the most widely adopted bio-derived matrix material to date in the composites industry. It is an excellent example of a bio-based polymer which has desirable properties that exceed its petrochemical equivalent: for example, high glass transition temperature and its fire, smoke and toxicity (FST) performance.

- polylactic acid (PLA), a thermoplastic with similar mechanical properties to polypropylene and has begun to be used as a replacement for other polymers in the packaging industry

- polybenzoxazines, thermosets with a very high glass transition temperature (up to 250 °C) which have been explored as potential replacements for phenolic resins in the aerospace industry.

Bio-derived, low carbon and natural fibres

Carbon fibre manufacture is predominantly petrochemical-based, using acrylonitrile monomer (ACN). ACN is polymerised and spun into fibre. A multi-stage pyrolysis process then removes any functionalisation leaving usable carbon fibre. This is a costly and energy-intensive process.

There are developments to reduce the carbon footprint of ACN. For example, bio-derived routes are now becoming available commercially (see the Solvay and Trillium case study). This aligns well with broader industry interests related to textile manufacture, where the sustainable sourcing of materials is a key consumer issue. Options for bio-derived drop-in replacements for polyacrylonitrile (PAN) in carbon fibre production are also being developed.

Read more about low carbon feedstocks in section 7.1 of our Chemistry-enabled sustainable composites technical report.

Composite manufacturing is energy intensive and contributes to the carbon embodied within a composite part. It also generates thousands of tonnes of consumable waste, like vacuum bags that are single use and not designed with sustainability in mind.

The common approaches used to manufacture most composites are:

- resin and fibre combination through processes such as manual lay-up, infusion, and resin transfer moulding

- consolidation, typically with the form under vacuum to remove entrapped gas and compressed with applied pressure (for example, through autoclave, or within a press)

- curing (if using a thermoset).

There are examples of how industry is incorporating more sustainable practices into the manufacture of composites, including:

- fast-curing resins or low-temperature cures that reduce the energy required to run ovens

- UV curing which has proven itself in some areas, including aerospace and energy (for example, for wind turbine blade repair or cure)

- moving to a vacuum-bag-only approach, with just an oven, to significantly reduce energy consumption.

Read more about sustainability in composite manufacture in section 7.2 of our Chemistry-enabled sustainable composites technical report.

Chemistry enables the durability of fibres and polymer matrices used in composites. It also plays an important role in the use of coatings and additives that protect them. This increases their resistance to environmental and in-service degradation, as well as fire. Chemistry can help by:

- sourcing more sustainable chemicals for additives from bio-derived or recycled sources (many performance-enhancing mechanisms rely on chemicals sourced from fossil fuels)

- collaborating more closely with material scientists and composite engineers to develop functional materials that enable detection of damage when it occurs.

Read more about increasing composite lifetime in section 7.3 of our Chemistry-enabled sustainable composites technical report.

Reuse represents an important strategy for reducing the environmental impact of FRPs. From a lifecycle perspective, reuse is generally preferential to recycling (see the waste hierachy). Reusing FRPs could be particularly valuable given their high inherent value and challenge to recycle.

Strategies for reusing FRPs:

- enhancing methodologies surrounding polymer identification (analytical chemistry)

- designing for the disassembly of large structural parts, for example, by developing reversible adhesives

- developing chemical strategies for structural health monitoring.

Reuse is still in its infancy. For example, the identification and requalification of composites remain significant challenges that would greatly benefit from more research and businesses working to facilitate it. However, chemical knowledge, techniques and research could play an important role in making reuse more commonplace.

FRPs can be damaged in a variety of ways, including impact, manufacturing defects, and environmental exposure. If damage is detected, repairing parts is a sustainable way of extending the lifetime of composites.

Strategies for repairing FRPs:

- composite patches that can be attached to a damaged structure

- liquid resin injection into pre-drilled holes within the damaged area, then curing it

- self-healing material that can be applied to design features, including section changes, ply drops, stringer run-outs, holes and joints. More research is needed to translate self-healing technologies into real-world applications.

Chemistry that underpins the development of easily repairable FRPs will accelerate the development of solutions in this field.

Read more about reuse and repair in section 7.4 of our Chemistry-enabled sustainable composites technical report.

As composites are made of two or more materials, recycling them is more complex than conventional materials like plastic packaging and metals. Recycling techniques need to be able to recover multiple distinct materials to avoid many composite parts ending up in landfill.

As the composite market grows so too does the problem of composite recycling. For example, in the wind industry alone, it is estimated that, by 2050, 190,000 tonnes of carbon fibre-reinforced polymer (CFRP) waste will have been generated. So far, much of the research into recycling composite material has only focused on the recovery of carbon fibre, and less on lower-value fibres. However, some methods have been identified that can recover other fibres and resin at the end of life.

Chemical recycling processes, such as solvolysis and thermolysis, enable fibres with minimal performance drop to be recovered, and the resin collected for reuse. In order to make these processes viable value needs to be derived both from the recovered fibre and the recovered polymer fraction.

Promising examples of solvolysis are highlighted in Section 7.5.2 of our Chemistry-enabled sustainable composites technical report.

However, a common problem preventing recycling is that the chemical makeup of materials is not always known. Composites often have a long lifetime and the materials used in their manufacture may not have been accurately logged as it passed along the supply chain. For composite recycling to become the norm:

- increased collaboration and information are needed along the supply chain to ensure that composites manufactured today can be easily identified

- sorting methodologies and analysis techniques need to be developed to identify and isolate the products of chemical recycling

- a better understanding of which chemical recycling techniques to apply to which composite types could highlight the standard approach for each composite class, adding great value to industry.

Several obstacles must still be overcome before there can be a new supply chain for recycled material but there are recycling technologies that show promise. To increase the uptake of composite recycling it must also become economically viable, which could be through increased penalties for non-recycling disposal strategies (i.e. legislation) or by ensuring the products recovered are of significant value.

Read more about chemical recycling technologies in section 7.5 of our Chemistry-enabled sustainable composites technical report.

Chemical recycling is not always possible. For next-generation composites there is an opportunity to design them for recycling into new materials.

Vitrimer development is one approach that the composites industry could adopt for developing inherently recyclable materials. They are crosslinked networks containing dynamic covalent bonds, known as covalent adaptive networks (CANs). These polymer networks have been shown to be processable or recyclable through exchange reaction of the dynamic covalent bonds.

Several viable routes to triggered degradation thermosets have also been identified and could offer routes to more easily degraded polymer matrix structures at acceptable cost. Crucially, these chemistries will need to be designed with industrially viable chemical recycling technology in mind and the associated separation processes.

Read more about inherently recyclable composites in section 7.6 of our Chemistry-enabled sustainable composites technical report.

Underpinning tools

Chemistry-based tools and approaches will enable the progression towards more sustainable composites to:

- aid new materials design and development for low carbon feedstocks and inherently recyclable materials

- detect and assess material degradation and damage for repair and reuse

- verify durability and performance prediction for enhancing composite lifetimes

- aid material identification for end-of-life processing.

Specific priorities for the chemicals sector include:

- supply chain digitisation (for example, the implementation of blockchain)

- a prototype materials and formulation database

- the use of big data

- digital design tools

- workforce upskilling.

Read more about underpinning tools in section 7.7 of our Chemistry-enabled sustainable composites technical report.

Opportunities and case studies

Chemistry underpins several elements of a composite. This means there are opportunities for the research community to help the composites industry achieve sustainability. We have identified six areas where the chemistry community has a role to play in developing sustainable solutions for the composites industry.

Chemistry can aid the transition from petrochemicals to bio-derived sources of carbon by:

- developing drop-in bio-derived replacements that match the performance of resins, fibres and other constituents derived from petrochemical feedstocks

- enabling the composites industry to adopt new chemistries made available from bio-derived sources to enhance performance.

As supply chains develop strategies to decarbonise, chemistry can support the composites industry to adopt waste and circular economy approaches to produce more sustainable composites. For example, by:

- maturing chemical recycling techniques for composites and other polymeric materials

- lowering the carbon content of synthetic routes to common composite materials.

As new composites come onto the market, chemistry can contribute to:

- improved chemical recycling techniques linked with materials design concepts (for example, triggered degradation and vitrimers)

- matching key material sets with efficient and high-yielding processing conditions for recycling.

Chemistry can help develop lower temperature cure systems and systems based on non-thermally activated mechanisms.

By harnessing the power of digital and computational chemistry approaches, the composites industry can better design new materials, predict performance, and bring new solutions to market, faster.

All the opportunities explored require broad support from government agencies through a UK advanced materials strategy and funding for chemistry related research for the composites industry.

Thanks to insights gleaned from industrial and academic workshops, desk research and sector knowledge, 19 chemistry-specific opportunities have been identified. Collectively, these cover all of the six themes above and could enable the development of sustainable solutions that benefit the composites sector as a whole.

Read more about the opportunities identified in section eight of our Chemistry-enabled sustainable composites technical report.

Case studies

You can find these case studies and more in our Chemistry-enabled sustainable composites technical report.

Championing the manufacture and use of more sustainable acrylonitrile

Acrylonitrile is found in all sorts of products we use in daily life, such as fleece clothing, tear-free shampoos, medical gloves and toy bricks. It is also a crucial precursor in the production of carbon fibre for the composite sector. Around six million tonnes of acrylonitrile – worth in the region of $14 billion – are produced and sold every year, from a predominantly petroleum-based supply chain.

Trillium is developing a technology called bio-ACN™ with the intention to build, own and operate the world’s first renewable acrylonitrile plant. The bio-ACN™ process uses proven chemical processing techniques to economically produce acrylonitrile at scale from plant-based feedstocks. This method minimises water and energy usage and reduces waste, while the carbon footprint of acrylonitrile drops by roughly 70% compared to the conventional petrochemical process.

Materials, chemicals and solutions experts at Solvay recently agreed to collaborate with Trillium to evaluate the use of bio-ACN™ for carbon fibre applications. Solvay’s carbon fibre-reinforced composite technologies already offer opportunities to cut weight and fuel consumption, and they can also reduce assembly costs by replacing metal parts frequently used in advanced applications, such as in transport and infrastructure. In working together to understand and demonstrate bio-ACN™ in the carbon fibre supply chain, Solvay and Trillium are working to deliver a lighter, cleaner and greener future.

Recyclability: working towards a new standard in the composite industry

Thermoplastic resin Elium® enables composites to be recycled in two different ways, making it very different to most current thermoset resin-based composites.

The starting monomer can be recovered through chemical recycling and is able to be reused in recycled resin production for the manufacture of new composite parts. And through mechanical recycling, it is possible to create a new object altogether.

This contrasts with most thermoset resin-based composites, which often are either sent to landfill or incinerated.

The resin is used in wind turbine blades, composite reinforcement bars for concrete (rebars) in the civil engineering sector, in hydrogen tanks and in sailboats. The three main benefits of these advances come in relation to mechanical performance, improved productivity in using the resin, and recyclability.

As an example of its practical uses, one of Arkema’s subsidiaries, Bostik, already has developed a structural adhesive for Elium® composite. During chemical recycling, the adhesive was found to boost, rather than hamper, the recovery of the monomer.

Increasing the energy efficiency and lifespan of wind turbines

Swiss company Gurit has developed RENUVO™, a glass fibre-reinforced polymer resin system that is designed to repair damaged wind turbine blades to extend their lifespan.

This technology allows more efficient energy generation by shortening repair times, which would otherwise cause lengthy operational downtime. It also requires no two-part mixing or heat to cure, cutting overall ancillary use, hazardous waste and cost – repairs can also be carried out in harsh environments, such as offshore wind farms. Through repairing rather than replacement, the lifespan of a turbine can be significantly increased, reducing the environmental impact of end-of-life concerns such as landfill.

RENUVO™ uses UV-activated polymer chemistry to form a structurally robust material. This allows the easy application and forming of wind blade repairs which can be hardened on demand to achieve the required strength and stiffness properties. The technology differs to traditional acrylate or methacrylate-based polymer systems in that it is free of solvents and monomers such as styrene. This lowers toxicity, improving the safety for users.

Gurit is a system partner for wind energy customers globally with a focus on wind turbine blades and hopes to enable the wider adoption of renewable energy to support the global decarbonisation goals.

Working to make computational chemistry more accessible to materials scientists

Simulations are used to help pharmaceuticals companies discover new drugs – and now they could be used to develop better polymer materials.

Molydyn’s Atlas platform makes molecular dynamics simulation easier than ever before. Through the use of artificial intelligence and decision making, Atlas allows all chemists to run simulations with inputs and outputs that they inherently understand. It enables chemists without modelling experience to benefit from simulations.

The initial focus for Atlas is to help academics teach the next generation of computationally-guided chemists and conduct more cost-effective innovative research. Chemistry students can now quickly access powerful tools and gain hands-on experience into how effective they can be. Simulation tools can also allow institutions with limited lab access to conduct cutting-edge research while keeping costs low, and it can help SMEs and universities compete with better funded research.

Molydyn is working to simultaneously make materials research more sustainable and develop materials that enable key green technologies, such as hydrogen storage. The drive to help scientists adopt computational chemistry approaches is the obvious opportunity.

Atlas can even simulate molecules that are hard to acquire or have never been synthesised. The platform can help companies design for end of life by simulating a multitude of polymers made with chemistries that are known to be easy to reprocess.